Organizing and securing your Rooftop Pipe Support Systems is necessary for ensuring both operational efficiency and safety. Properly designed pipe support systems prevent damage to the roof surface by evenly distributing weight and reducing pressure points, while also helping maintain a tidy and accessible layout for rooftop infrastructure.

This organization not only extends the lifespan of the roofing materials but also enhances the overall reliability of the systems in place. Additionally, access platforms are crucial for providing safe, stable pathways to rooftop equipment, allowing maintenance personnel to perform their tasks conveniently and securely, even in challenging environments.

What Are the Benefits of Using Pipe Support Systems on Roofs?

The primary reasons HVAC systems are placed on building rooftops are to provide easier access for maintenance and repairs, save valuable interior space, improve airflow and ventilation, reduce noise pollution inside the building, and to act as a deterrent against theft and vandalism.

Locating HVAC on commercial building rooftops has its share of challenges, though: how do you safely access your HVAC equipment for maintenance, and what do you do with all of the pipes? In addition to any HVAC condensate lines or electrical conduit pipes that are directly related to your rooftop HVAC, there may also be drainage pipes, vent pipes for plumbing systems, or leader pipes for directing water to drains. These needs to be organized in a safe, efficient way that minimizes impact to your roof.

Pipe support systems offer numerous advantages for rooftop installations, ensuring long-term efficiency and durability. By evenly distributing the load of pipes and equipment, these systems prevent concentrated pressure points that can damage roofing materials, which helps reduce the risk of leaks or structural issues. They also protect roof surfaces from wear caused by direct contact or shifting pipes.

Rooftop pipe support systems promote an organized layout for piping networks, making maintenance easier and reducing the likelihood of tangled or obstructed systems. These benefits make pipe supports a critical component of safe, efficient, and well-maintained rooftop infrastructure.

The Role of Access Platforms in Rooftop Efficiency

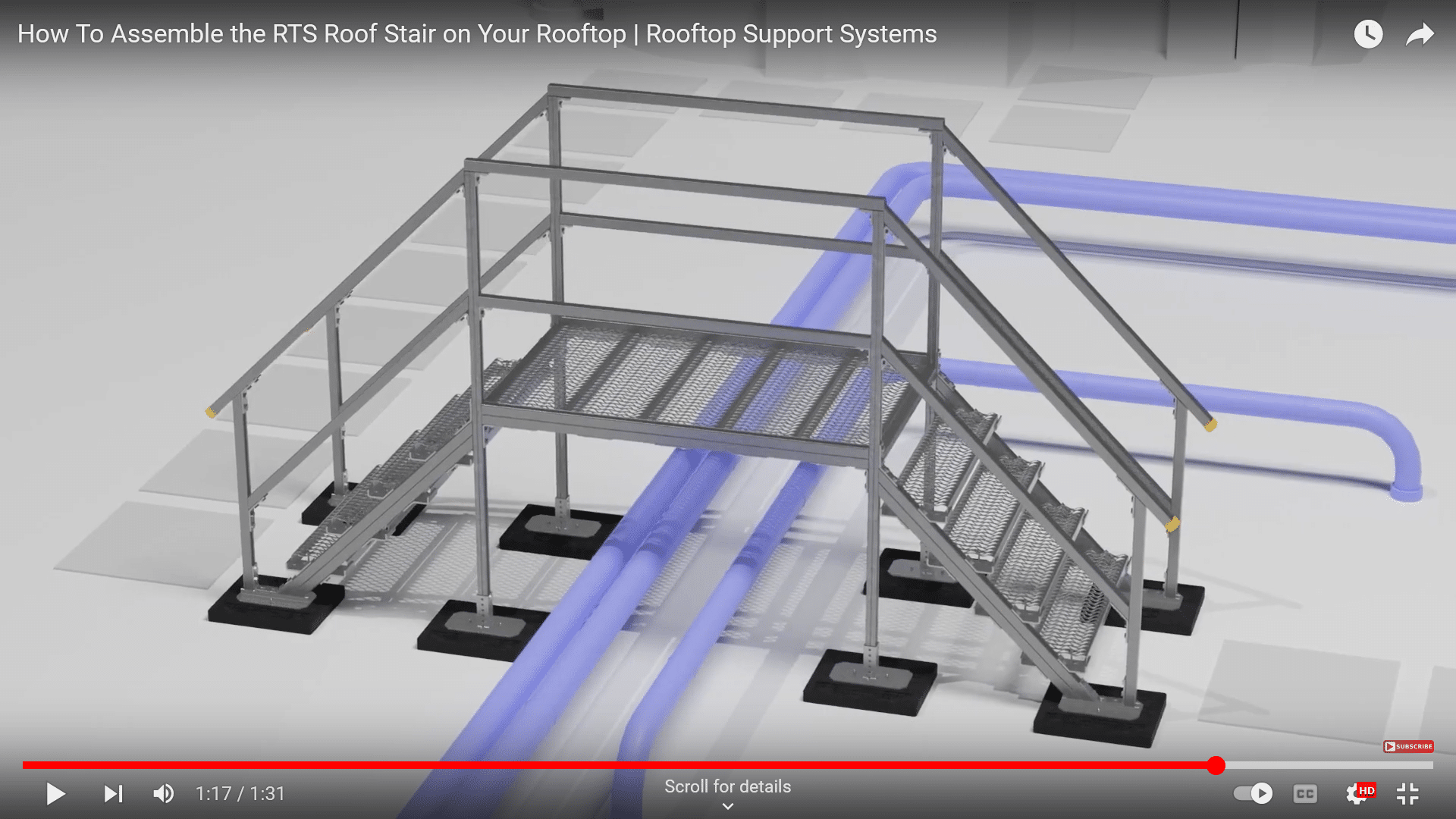

Access platforms exist to provide workers with safe access to rooftop equipment. Elevated access platforms allow workers to navigate around obstacles like pipes, ducts, and cables while safely reaching panels and doors for repairs and inspections, all while minimizing the risk of falls and injuries on the roof. They help reduce the risk of accidents and damage to critical infrastructure.

They also enhance efficiency by streamlining movement across the rooftop, allowing workers to perform inspections, repairs, or maintenance tasks with ease and confidence. These platforms are an important component of any well-organized rooftop setup, prioritizing safety and functionality.

Design Considerations for Access Platforms

When choosing access platforms, key design considerations include type of platform, durability, material selection, ease of installation, and compliance with safety standards.

Side access and end access platforms are two distinct types of access platforms designed to provide safe and efficient pathways for maintenance personnel.

Side access platforms are raised platforms that typically include stairs at two ends and a walkway between that is open on one side to provide access to equipment panels and doors. They are positioned alongside equipment or structures, allowing workers to reach components from the side. These platforms are ideal for operations requiring extended lateral movement or when space constraints make front access impractical.

End access platforms, on the other hand, typically include only a single set of stairs that lead directly to up to the door or access panel that needs to be accessed. While both ensure safety and stability, side access platforms may be preferred for larger equipment, as they offer the ability to provide access to a greater area and can encompass multiple service panels, doors and other necessary access points along a large piece of rooftop equipment.

Durability must also be heavily considered, as it ensures the platform can withstand harsh weather, heavy foot traffic, and long-term use without compromising performance. Materials like galvanized steel or aluminum are popular choices for their strength and corrosion resistance. Popular finishes include pre-galvanized, hot-dip galvanized, and stainless steel, all of which are readily available through the RTS website.

Ease of installation is also crucial, as modular or prefabricated designs can reduce labor costs and minimize disruption during setup. Compliance with safety standards, such as proper railing height and non-slip surfaces, guarantees worker protection. A well-designed access platform ensures stability, safety, and longevity, making it a reliable solution for rooftop access.

Types of Pipe Supports for Rooftops

When it comes to selecting the proper pipe supports for your needs, there are several factors to consider:

Penetrating vs Non-Penetrating: Penetrating rooftop pipe supports are anchored directly into the roof structure, providing maximum stability and load-bearing capacity, making them ideal for heavy-duty installations or areas with high wind loads or seismic activity.

Non-penetrating pipe supports, on the other hand, rest on the roof surface without puncturing it, relying on distributed weight and friction for stability. These are preferred when preserving roof integrity and avoiding leaks is a priority, such as with flat or membrane roofs. Choosing between the two depends on the roof type, load requirements, and the need for structural protection.

Low Profile vs Elevated: Low-profile rooftop pipe supports keep piping closer to the roof surface, making them ideal for installations with height restrictions or where a sleek, unobtrusive design is preferred. They are often used in areas with minimal snow accumulation or low clearance requirements.

Elevated pipe supports, however, raise piping above the roof surface, providing better protection from debris, water pooling, or snow buildup, and allowing for improved airflow and drainage. The choice between the two depends on environmental conditions, maintenance needs, and space constraints.

Light Duty vs Heavy Duty: Light-duty rooftop pipe supports are designed for smaller, lighter pipes, such as gas lines or electrical conduits, which may have larger diameters but lower weight. These supports are economical and ideal for less demanding applications.

Heavy-duty rooftop pipe supports, on the other hand, are built to handle larger, heavier loads, such as liquid-carrying pipes, which are often dense and weigh significantly more. Choosing between the two depends on the pipe material, size, weight, and the load-bearing capacity required to ensure stability and long-term performance.

Types of Pipe Connections: There are several types of common pipe connections designed to secure piping and accommodate specific installation needs. Strut clamps are versatile and commonly used for securing pipes to strut channels in fixed positions, ideal for stable applications. Clevis hangers provide suspended support, allowing vertical adjustment and flexibility, making them suitable for plumbing or HVAC systems. Pipe rollers accommodate movement caused by thermal expansion or contraction, reducing stress on the piping system and are often used in industrial applications where pipes carry hot or cold fluids. The choice of connection depends on whether the system requires fixed positioning, vertical support, or the ability to manage dynamic movement.

Products for Pipe Supports and Access Platforms by Rooftop Support Systems

Rooftop Support Systems offers a wide range of innovative pipe support and access platform products designed to enhance safety and efficiency for rooftop infrastructure. Our Adjustable Pipe Supports feature durable, weather-resistant materials and are ideal for supporting HVAC, plumbing, and electrical conduits while protecting roof surfaces from damage.

Our Modular Access Platforms provide safe and customizable pathways, perfect for navigating over pipes, equipment, and other obstacles, with anti-slip surfaces and compliance with safety standards. These products are easy to install, reduce maintenance challenges, and ensure a well-organized, long-lasting rooftop setup, making them a reliable choice for diverse applications.

Find more Rooftop Pipe Support Here: https://rooftopsupportsystems.com/products/rooftop-pipe-supports/

Find More Rooftop Access Platforms Here: https://rooftopsupportsystems.com/products/access-platforms/

Enhancing Rooftop Efficiency and Safety

Pipe support systems and access platforms are essential for optimizing rooftop installations, offering numerous benefits such as protecting roof surfaces, evenly distributing loads, and maintaining an organized infrastructure layout. These systems enhance safety by preventing damage and creating secure pathways for maintenance personnel, while also improving the efficiency and longevity of rooftop equipment. Rooftop Support Systems provides a wide range of customizable solutions tailored to meet the specific needs of any project. Explore their products today to ensure your rooftop setup is safe, durable, and designed for maximum performance.

Ready to Get Started with us on your next Rooftop Project?

1 (888) 243-2669