Wind Resistance Options for Roof Mounted Duct Work

One of the most important considerations when designing and evaluating installation of rooftop duct supports is the wind load capacity and the effect the wind will have on the system. Wind load ratings must fall in line with the expected wind loads for the region of installation.

According to the Uniform Building Code, typical wind load requirements range from 60 to 120 mph. In high-wind regions and coastal areas, such as Florida, installations are required to meet 160+ mph requirements.

There are several different ways to incrementally increase the wind rating of rooftop duct supports.

** Wind load capacity of any system needs to be evaluated by an engineer, but the following can be used as general guidelines:

Non-Penetrating Options

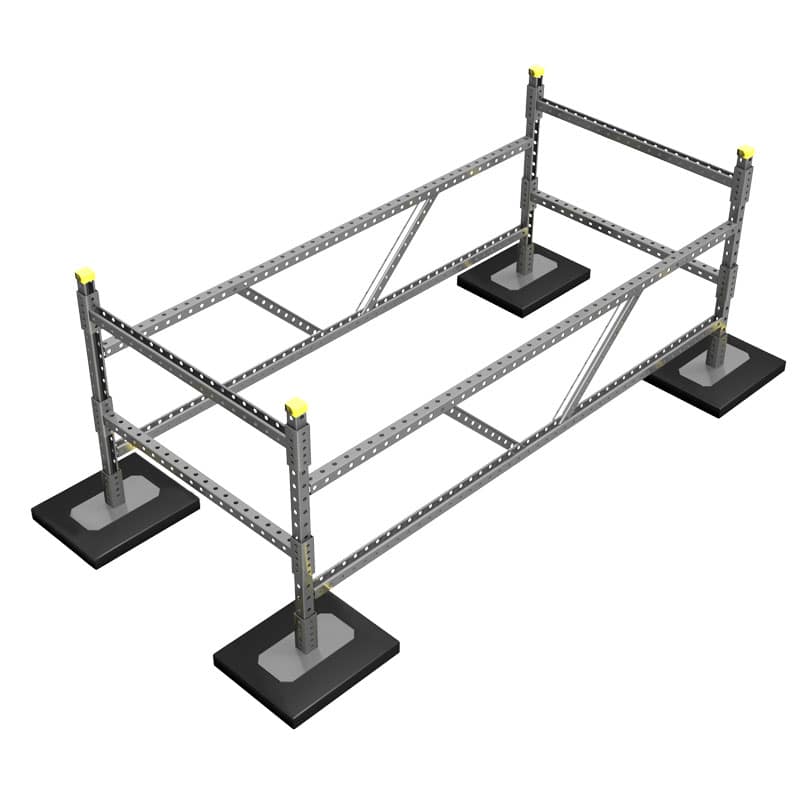

- Add a Pinch Bar: this is an additional cross brace installed above the duct to prevent wind from blowing the duct up and off of the support. The weight of the supports may be enough to meet the wind requirement for short or sheltered duct runs.

- Add Wind Bracing: connecting all of the supports into a single array not only increases the weight of the entire system, but it creates a more rigid installation. This will increase the wind resistance of the system over pinch bars alone.

- Add Supports: by decreasing the spacing between the H-Stands and still using the additional bracing, the weight of the system is increased, increasing the wind uplift resistance. Until this point, no roof penetrations have been required.

Until this point, no roof penetrations have been required. There comes a point, however, where the system has to be anchored to the building structure to meet the project requirements.

Penetrative Options

- Install Wind Tie-Downs: Tie downs can be installed beneath a single H-stand or centered between two adjoining stands. The advantage is reducing the number of roof penetrations. Depending on the requirements, these could be installed at every, every other, every third, etc. support. An engineer is to determine locations of tie downs, type of anchor, and type of cable to use.

- Direct-Mount Bases: Using direct mount bases rather than the non-penetrating rubber bases provide the best wind uplift resistance. Similar to the Tie Down’s, an engineer is to determine how many supports require direct mount bases, and the type of anchor to use with them. Obviously, the more stands that utilize the direct mount bases, the higher the achieved wind rating will be.