In geographic locations where seismic is likely to occur or seismic regulations exist, seismic bracing for piping systems is a necessity. This applies especially for rooftop installations such as HVAC, water, gas, and fire protection pipes, as their continued operation is paramount during and after seismic events. These systems play a vital role in maintaining building functions such as temperature control, water distribution, and fire suppression.

Proper seismic bracing ensures that these pipes remain stabilized and operational during earthquakes, preventing them from shifting, breaking, or leaking. Effective bracing not only protects the structural integrity of the piping but also ensures compliance with seismic regulations, reducing the risk of system failure, property damage, and safety hazards. By securing rooftop piping, building operations can continue uninterrupted during seismic events, protecting both property and occupants.

What Is Seismic Bracing for Piping?

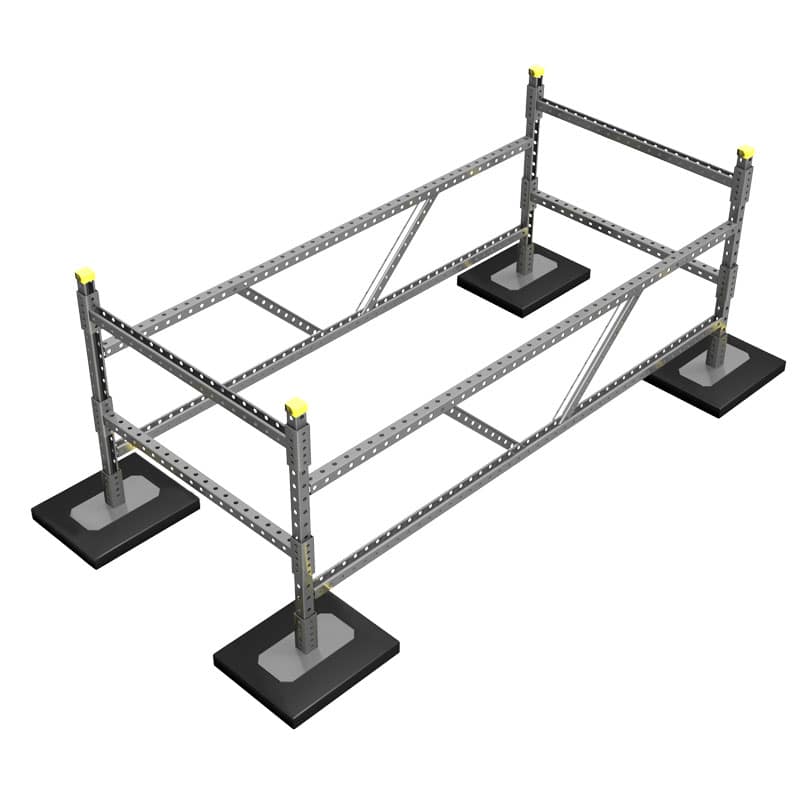

Seismic bracing for piping involves a system of components designed to secure piping systems and prevent them from shifting, collapsing, or sustaining damage during an earthquake or other seismic activity. The primary components include brackets, anchors, braces, sway bars, and fasteners, which are strategically installed to connect the pipes to the building’s structural elements, like rooftops.

These components work together by absorbing and redistributing the seismic forces that would otherwise cause the piping to move or fail. Horizontal and vertical braces stabilize the piping in multiple directions, while anchors and sway bars ensure the system remains securely fastened to the rooftop, reducing stress on the joints and preventing ruptures or disconnections. This integrated approach ensures that piping systems remain functional and safe during seismic events, protecting important building operations.

The Importance of Seismic Bracing for Piping Systems

Seismic bracing is a necessity for rooftop piping systems primarily because it helps ensure these pipes can withstand the intense forces generated during an earthquake, significantly reducing the risk of system failure. Proper bracing stabilizes pipes, preventing them from swaying, shifting, or collapsing, which can cause severe damage not only to the pipes themselves but also to the building and its support structures.

Without adequate bracing, gas pipes could rupture, leading to potential explosions, while water or fire suppression systems could leak or become depressurized, resulting in system failure when they are needed most. This can lead to catastrophic consequences, including flooding, fire hazards, and even structural damage to the building. By securing pipes with seismic bracing, you protect both the integrity of essential systems and the overall safety of the building and its occupants during seismic events.

How Does Seismic Bracing Help Ensure Piping System Stability?

Seismic bracing supports piping systems during earthquakes by absorbing and redistributing the seismic forces that would otherwise cause pipes to shift, vibrate, or break. Bracing systems are strategically placed to anchor pipes at critical points, reducing excessive movement in both horizontal and vertical directions. This stabilization minimizes swaying and dampens the vibration that occurs during seismic activity, preventing strain on pipe joints and connections. The bracing system’s ability to control vibrations and limit displacement protects not only the pipes themselves but also the building structure and essential systems like gas, water, and fire suppression, which are vital for safety and continuity during a seismic event.

Designing Effective Seismic Bracing for Pipe Systems

When designing seismic bracing for piping systems, several key factors must be carefully considered, including pipe size, weight, and the material being transported through them. Heavier pipes, or those carrying high-pressure materials like gas or water, require more supports to prevent excessive movement during an earthquake. The distance between supports is also influenced by these factors—larger, heavier pipes need closer bracing intervals to ensure ideal stability.

Direct mounting of supports may be necessary to provide a secure connection to the building’s structure, while tie-down bases can help secure pipes on rooftops, preventing lateral movement. The bracing must also evenly distribute the weight across the rooftop, reducing stress on the building’s surface. Systems like Unistrut seismic bracing are commonly used for this purpose, offering versatile, adjustable solutions that securely anchor piping while maintaining flexibility for different pipe configurations and materials, ensuring the system remains stable during seismic events.

Top Selling Wind & Seismic Bracing Products

Common Challenges in Seismic Bracing for Piping

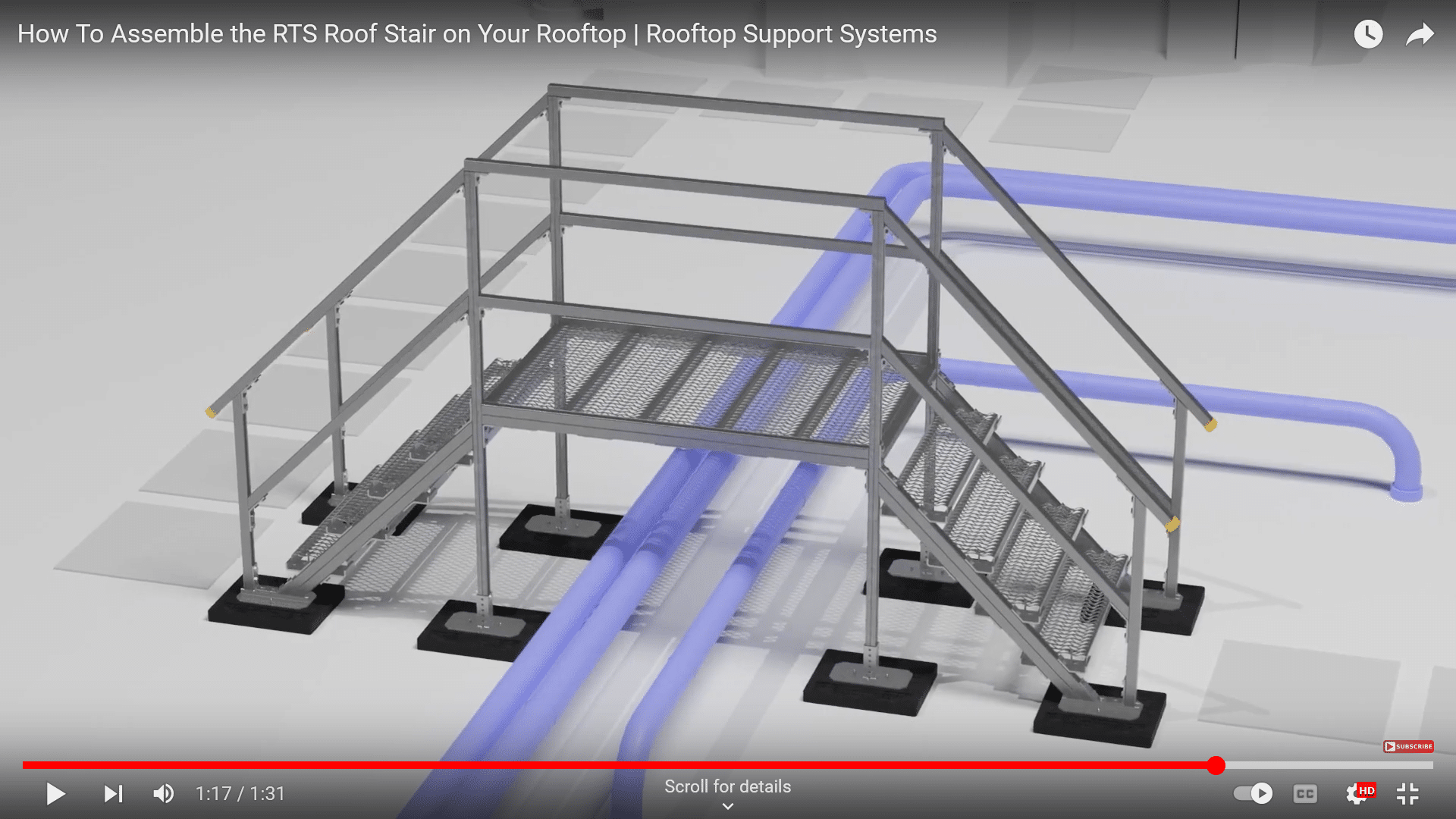

Bracing piping systems often presents challenges due to complex roof layouts, changes in elevation, and varying roofing materials, all of which can complicate the installation of stable supports. For instance, uneven rooftop surfaces or roofs with multiple levels may require customized bracing to ensure even weight distribution and stability across different sections. Additionally, roofing materials like metal or membrane may necessitate specific mounting methods to avoid damage while providing adequate anchoring.

Our products, such as adjustable Unistrut seismic bracing and tie-down bases, offer versatile solutions to these challenges by providing flexible, modular systems that can adapt to changes in elevation and roof complexity. These systems are designed to securely anchor to various roofing materials without compromising the integrity of the roof, ensuring the piping remains stable and functional in all conditions and scenarios.

Real World Applications and Case Studies

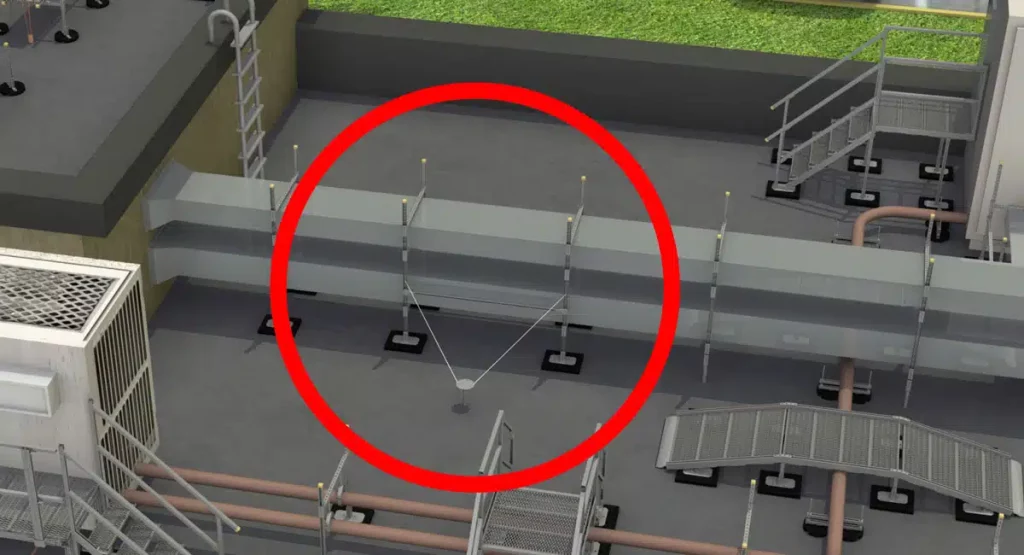

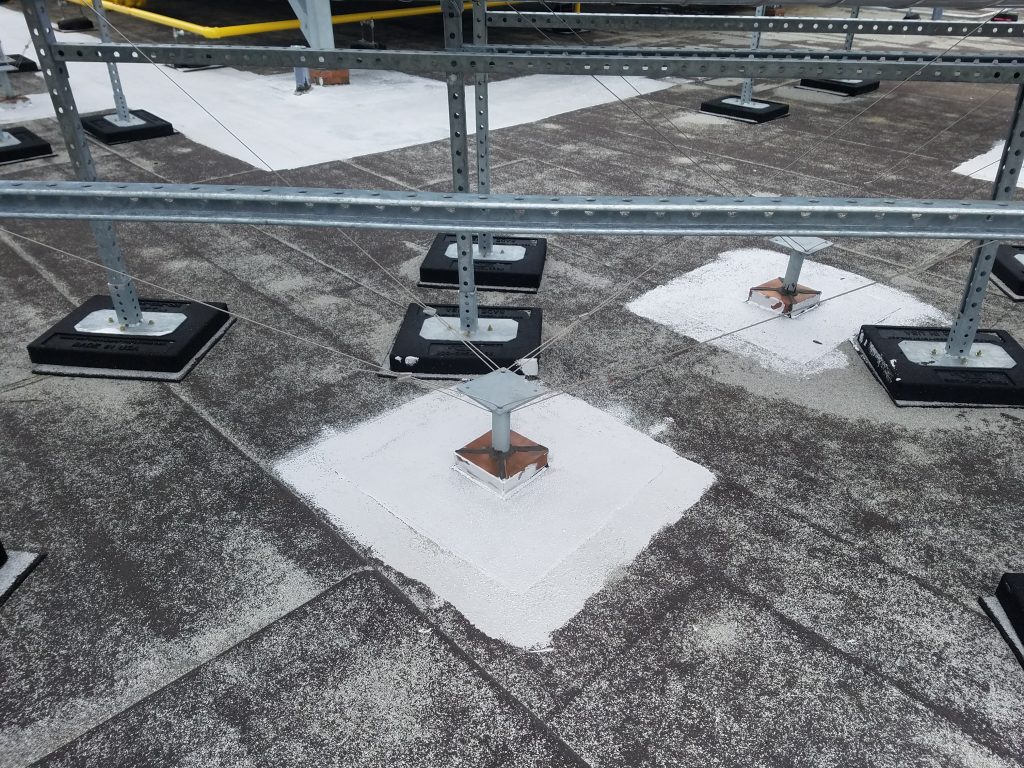

Hospitals, as critical infrastructure, require highly reliable systems to remain operational during seismic events. This makes them prime candidates for robust seismic bracing implementations. In one notable project for a local major healthcare facility, our H-stand pipe supports were installed in conjunction with tie-down bases that were flashed into the roof, ensuring that vital systems would stay functional during any potential seismic activity.

The project’s key takeaways included the importance of precise planning and coordination to work around complex mechanical systems while ensuring compliance with strict healthcare regulations. Our team delivered a tailored bracing solution that addressed both the weight and layout of the rooftop pipes, effectively securing them without interrupting the facility’s day-to-day operations. This project showcased our expertise in creating customized, code-compliant bracing systems that ensure the safety and continuity of essential services in critical environments like hospitals.

Seismic bracing for piping systems is a necessity for safeguarding critical building functions during earthquakes, protecting against catastrophic failures such as gas leaks, water system disruptions, and structural damage. Ensuring compliance with seismic regulations not only enhances safety but also fulfills legal and code requirements.

Rooftop Support Systems is committed to providing expert consultation, custom solutions, and comprehensive support to meet the unique needs of each project. Our tailored bracing systems are designed to secure vital infrastructure while maintaining operational integrity, giving clients the confidence that their systems will remain stable and functional in the event of a seismic event.

Ready to Get Started with us on your next Rooftop Project?

1 (888) 243-2669