Maintaining a commercial roof requires safe, reliable access to equipment and service areas, but traditional construction methods for rooftop platforms can be time-consuming and costly. That’s why prefabrication has become the smarter, more efficient option. Our prefabricated structures are engineered, assembled, and packaged in a controlled warehouse environment, then shipped directly to the jobsite for quick installation. By the time they arrive, these roof platforms are ready to be lifted into place, reducing labor hours and improving overall project efficiency.

For facility managers, contractors, and specifiers, prefabricated solutions are transforming the way commercial roof maintenance is handled. From equipment platforms to access platforms, every component is designed for strength, safety, and ease of use. With prefabrication, you not only save on time and cost but also gain peace of mind knowing your roof safety equipment is built to consistent, repeatable standards.

Prefabricated Steel Structure Built in a Controlled Warehouse Environment

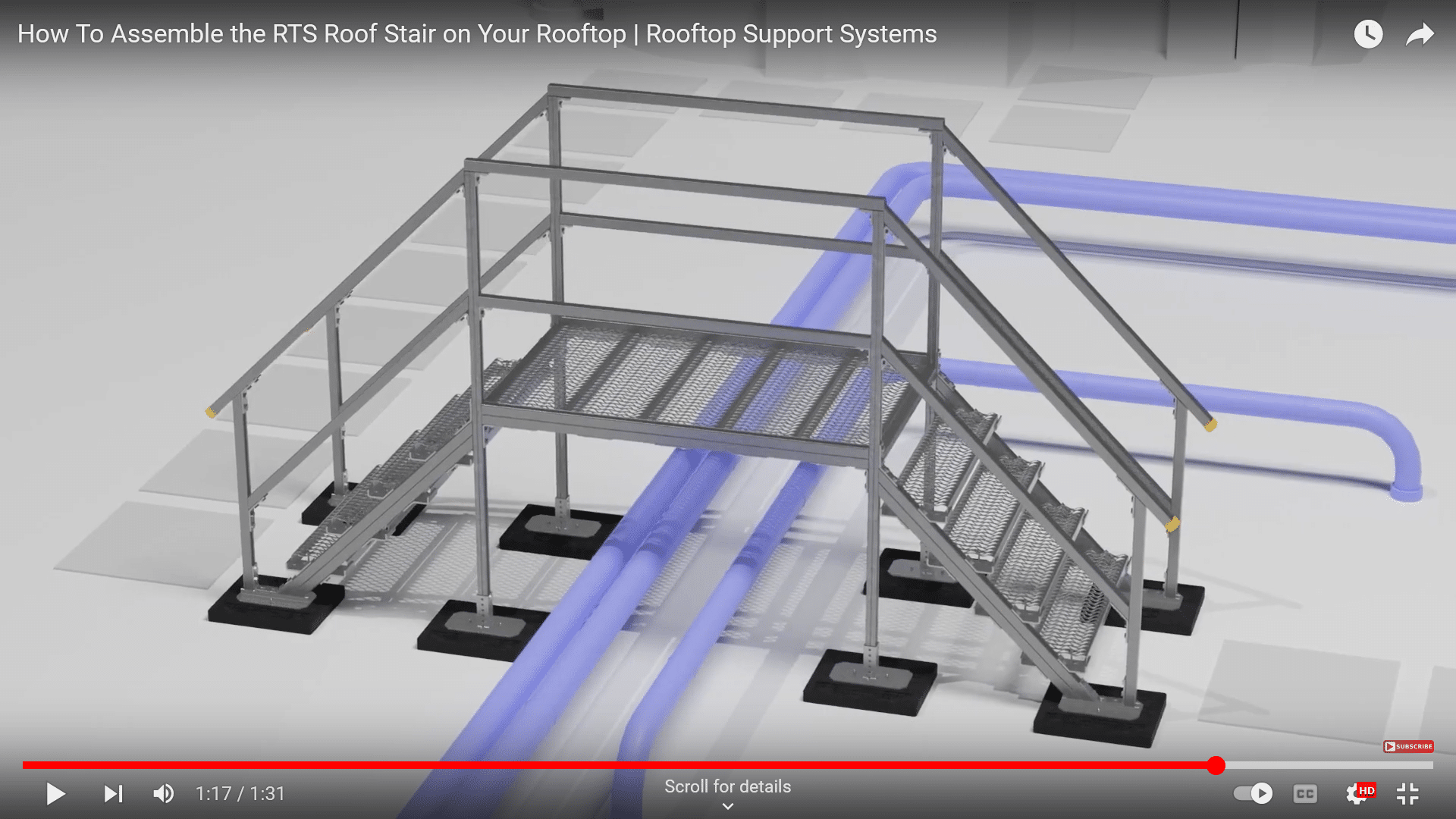

The process begins in our warehouse, where every prefabricated steel structure is built from Heavy-Duty Modular Square Framing (HDMS). Constructing these systems in a controlled environment ensures the highest levels of precision and quality. Components are assembled and connections are made under consistent conditions, eliminating the variability that often comes with on-site work. By the time the structure leaves the facility, it has already passed strict internal quality checks.

Building in-house also allows us to prepare all supporting elements in advance. Railings, ladders, and bases are included as part of the prefabricated steel framing system, ensuring nothing is left out or overlooked. This approach not only improves safety and compliance but also guarantees the system will assemble exactly as designed. For contractors, this means fewer surprises in the field and a platform that performs as intended from day one.

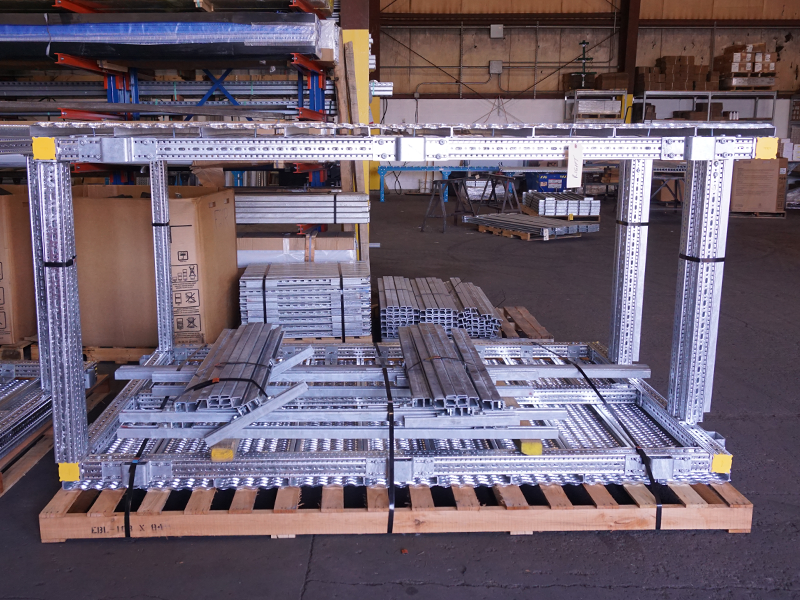

Nesting Components & Shipping Prefabricated Modular Structures

Once fabrication is complete, our team carefully nests the components for transport. Railings, ladders, and non penetrating roof mount bases are securely packed inside the frame, creating a compact load that minimizes shipping space. This method reduces freight costs and provides greater protection for the components during transit, ensuring they arrive at the jobsite ready for assembly.

By consolidating multiple prefabricated modular structures onto a single flatbed, we also streamline logistics for larger projects. This nesting process not only improves efficiency but also makes it easier for contractors to manage inventory on-site. Everything arrives as a single, organized shipment, which cuts down on handling time and helps crews get right to work.

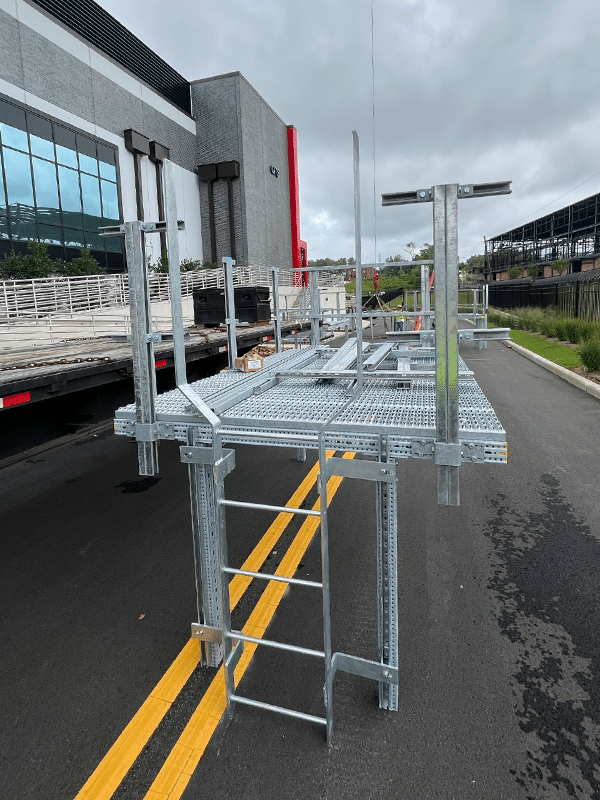

Prefabricated Structures Offer Simple On-Site Assembly with Minimal Tools

When the roof platform reaches the jobsite, installation is straightforward. Unlike traditional systems that may require welding or cutting, our modular platforms are designed for fast, bolt-together assembly – with most of the structure already preassembled. With just a simple wrench, crews can secure railings, ladders, and bases in place, transforming the preassembled components into a fully functional structure in a fraction of the time.

This ease of assembly translates into major labor savings. Contractors can deploy smaller crews while still finishing jobs faster, freeing up resources for other tasks. Reduced on-site work also minimizes safety risks associated with hot work or extended rooftop activity. For building owners, the result is a quicker, safer installation process with less disruption to daily operations.

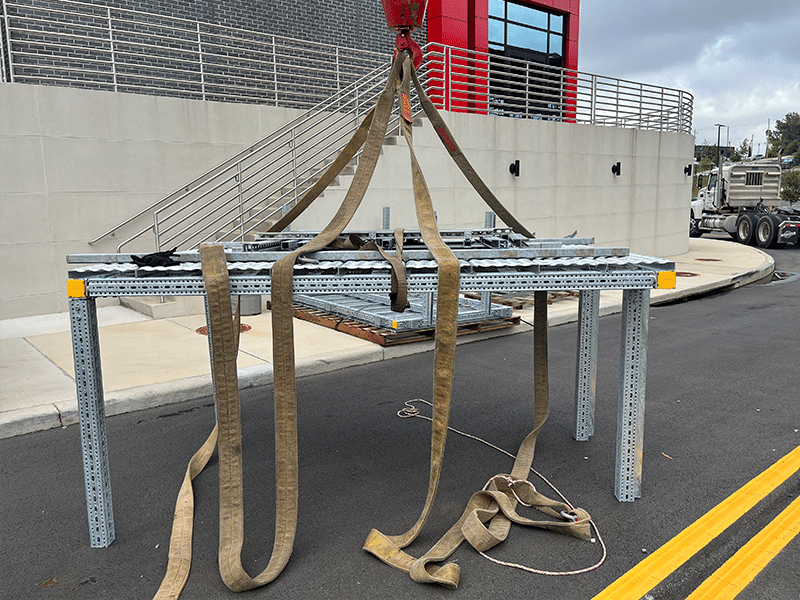

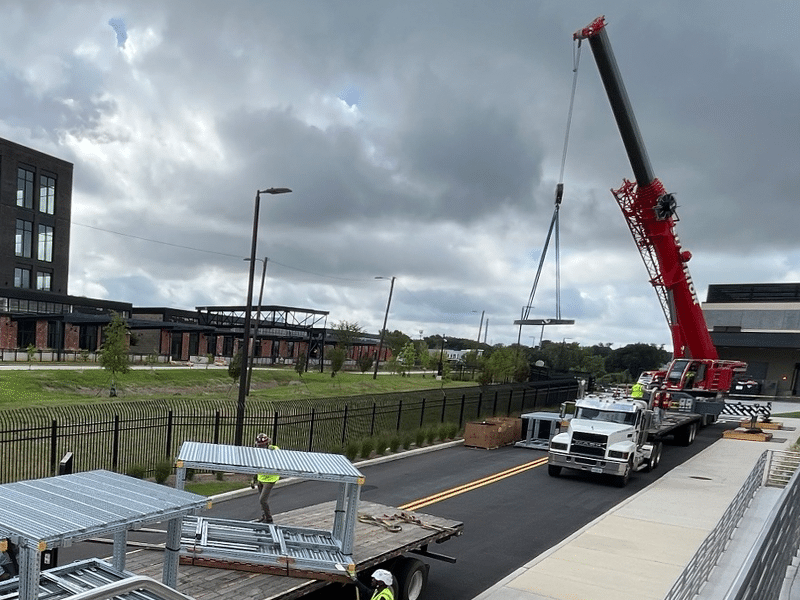

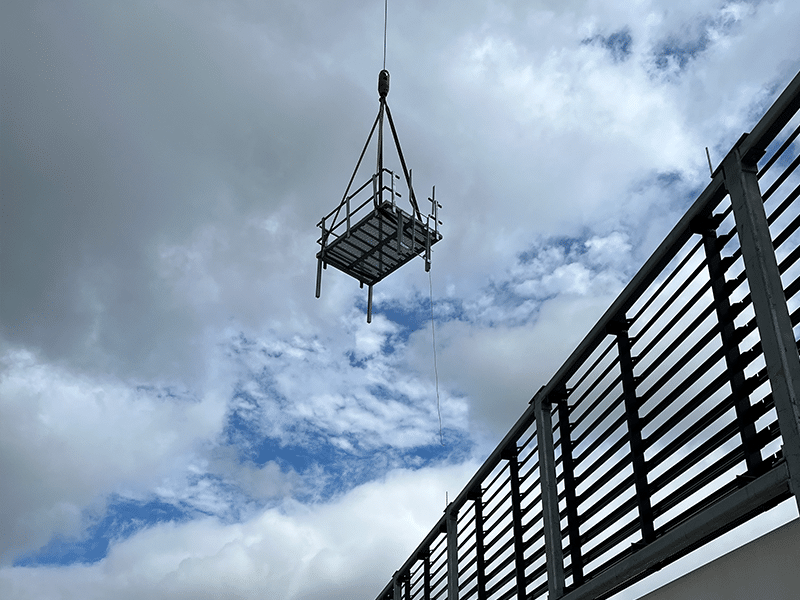

Lifting Roof Platforms into Place on Roof

Once assembled, the equipment platforms or access platforms are ready to be hoisted directly onto the roof. Because each system rests on non penetrating roof mount bases, manufactured from recycled rubber, no drilling or cutting is required. This preserves the integrity of the roof membrane while still providing a strong, stable foundation for service and maintenance activities. Direct mount options are also available for areas with high wind or seismic activity.

The ability to lift entire assemblies into place is another key advantage of prefabrication. Crews spend less time moving parts individually and more time focusing on safe, efficient placement. Whether you need a single maintenance platform or multiple rooftop platforms, the installation process is designed to maximize speed without sacrificing safety or durability.

A Prefabricated Steel Framing System = Time & Cost Savings

Prefabrication offers measurable benefits in both time and cost savings. By building off-site and delivering ready-to-install systems, we reduce the need for specialized labor and eliminate costly delays caused by weather or jobsite conditions. Projects stay on schedule, and budgets stay under control.

For facility managers, these savings extend long after installation. Durable roof support structures and heavy modular frame designs reduce the need for repairs and make ongoing commercial roof maintenance safer and more efficient. Investing in prefabricated modular structures means investing in a long-term solution that delivers consistent performance and lasting value.

Ready to Get Started with us on your next Rooftop Project?

1 (888) 243-2669