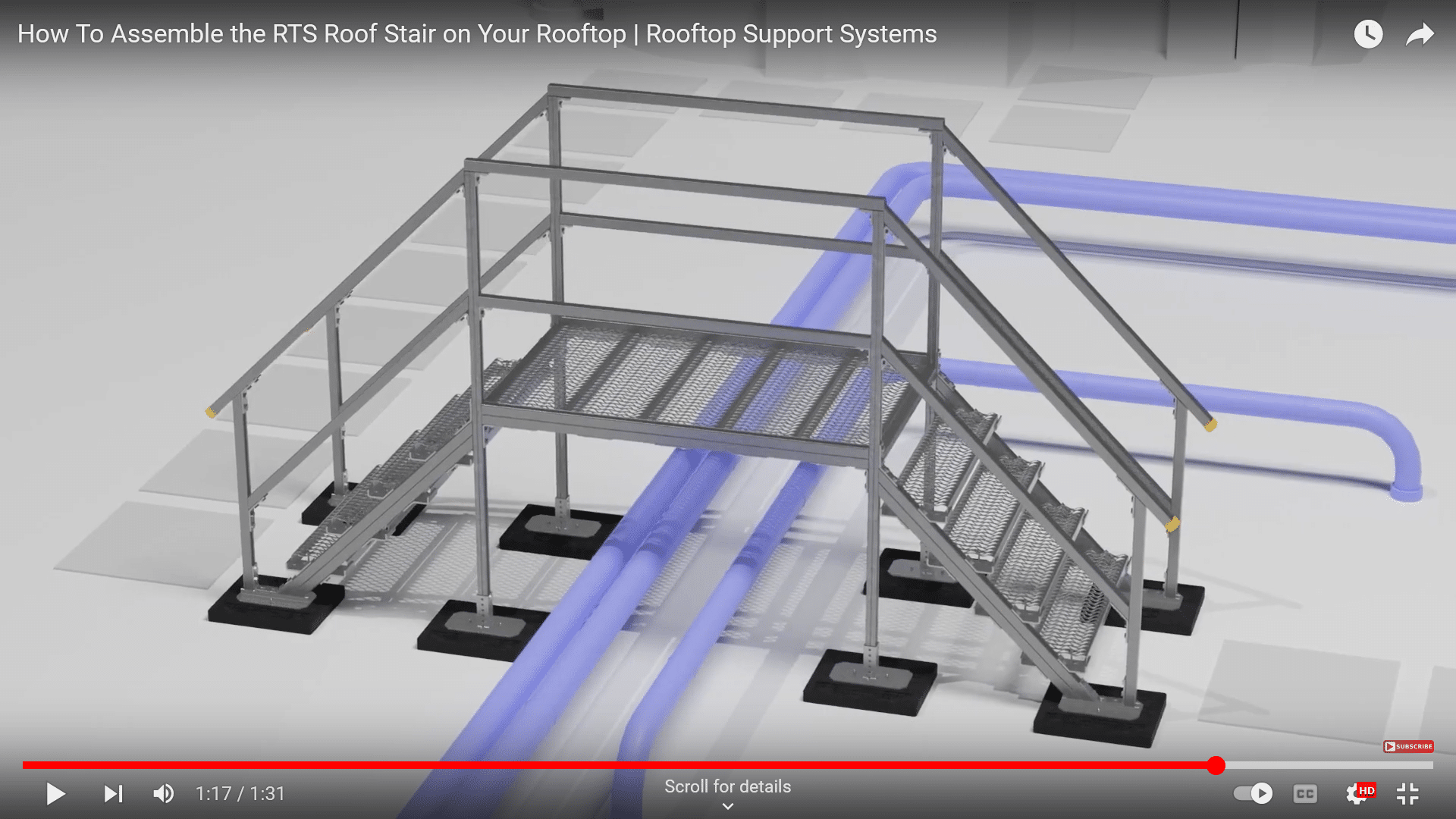

Roof Pipe Supports That Save You Time & Money

Our Rooftop Support Systems division recently received an order from a large biotechnology/therapeutics company in Cambridge, Massachusetts for over 120 roof pipe supports. After filling the order and shipping it out to the customer, we decided to see just how well our supports compared to our competitor’s products. Below is our roof pipe supports case study. What we found will surprise you!

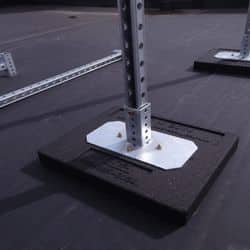

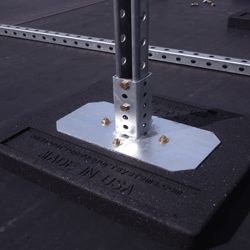

We started off by listing the pieces that we needed to successfully assemble one of our roof pipe supports. The list included:

- (2) RTSF21 Bases

- (2) RTSUR6PG Uprights

- (2) RTSFB48PG Cross Braces

- (6) Sets of Hardware (P3008-ZD and 3/8″ x 1″ bolts)

- (2) Yellow End Caps

- (2) Snap Pins

Next, we listed the necessary pieces to assemble the roof pipe supports offered by our competitors. Their list included:

- (2) RTSF21 Bases

- (2) RTSUR6PG Uprights

- (2) pieces of 48″ Strut (Cross Braces)

- (4) Sets of 3/’8″ Hardware

- (16) Sets of 1/2″ Hardware (P3013-ZD and Bolts)

- (4) P2484-EG (Corner Brackets)

Our Roof Pipe Supports Require Zero Brackets And Less Hardware To Assemble

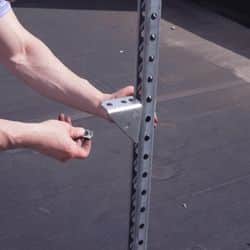

From a material standpoint, we saw that our supports required less pieces to assemble because our cross braces are pre-made to easily slip over the uprights, rather than attaching the cross braces to the uprights using brackets. We also saw that we needed significantly less hardware to assemble the entire support. From a cost standpoint, we were able to price out the material needed to assemble the two different pipe supports. We found out that our supports are 35% cheaper than the competitor’s.

We then moved on to the actual assembly of the roof pipe supports to see how we stacked up against our competitors. We weren’t surprised by the results of the timed tests. We tasked one person to assemble the competitor’s support. He was given the necessary tools, all the pieces and hardware and the instruction sheet that our competitor’s hand out with every order. The clock was started and our engineer started assembly. With the sun shining down and the rooftop temperature rapidly increasing, our engineer had to call it quits after 30 minutes of working on the support.

During this time, only half of the support was able to be put together. The directions were unclear, there were too many pieces of hardware to keep track of and the brackets required too much effort to deal with. A short break was taken and the timed test was repeated. This time our engineer had to put together our roof pipe support. Again, he was given the necessary tools, all the pieces and hardware and the instruction sheet that we provide with our orders. The clock was started and our engineer went to work. After 12 minutes, the clock was stopped. Our engineer successfully assemble the entire roof pipe support.

Our Roof Pipe Supports Take 50% Less Time To Assemble

To recap, we compared our roof pipe supports to the competitor’s supports to find out how much better we really are. Here are the results and what they mean for you.

- Our roof pipe supports require less pieces to assemble. No brackets are needed to support the cross braces because our cross braces are pre-made to slide over the uprights. This means less hardware and less headaches.

- Our roof pipe supports cost 35% less than our competitor’s product This can amount to HUGE SAVINGS!!

- Our roof pipe supports can be assembled more than 50% faster. Our systems are much more user friendly and can result in significant savings in labor cost.

In conclusion, we blew the competition away in every category, clearly showing that our roof pipe supports save you time and money. For more information on the Rooftop Supports we offer or to request a quote, click the button below!