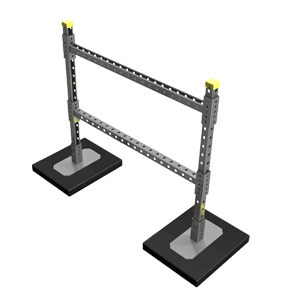

H-Stands work great for supporting your pipes and ducts!

When looking for an effective rooftop support system that can support your pipes and duct work, look no further than our H-Stands. Our custom designed H-Stands are manufactured in house to meet your job specific needs, but did you know that the framing and hardware comes in a variety of finishes? Choosing which type of finish to use on your H-Stands may seem a little confusing, but our team of project mangers have years of experience and can help you choose which type of finish is right for you. Below is a explanation of the types of finishes offered as well as a detailed chart explaining the service life of each finish.

Framing Finishes for H-Stands

Pregalvanized Finish: ASTM 653. Zinc thickness = .75 MIL thick or .45 oz/ft². This pregalvainzed finish is the same finish found on the sheet metal used to make duct work. The finish is applied by feeding the steel through a zinc coater. This type of finish for your H-Stands is a time-tested, well proven performer for interior and normal exterior applications.

Hot Dip Galvanized Finish: ASTM 123. Zinc thickness = 2.6 MIL thick or 1.5 oz/ft². For this finishing process, the steel is cleaned in an acid bath to remove impurities and then immersed in molten zinc. The coating is much thicker and more resilient than the previously mentioned pregalvanized finish. Hot dipped framing should be used for H-Stands that will be exposed to a more corrosive environment, such as coastal areas where ocean salt can expedite the corrosion of the H-Stands.

Hardware Finishes for H-Stands

Electroplated Zinc (Perma-Gold): ASTM B633 Tyle II SC3. The parts that are plated with this finish are immersed in a solution of zinc ions then an electric current passes through the hardware which causes the zinc to attach to the steel. The final result is a coating with a .5 MIL thickness. The SC3 designation is meant for more severe applications and is more corrosion resistant.

Hot Dip Galvanized Finish: DO NOT USE….EVER! While this finish if more resilient than the previously mentioned electroplated zinc finish, the dipping process clogs the threads in the nuts and bolts which essentially renders the hardware for your H-Stands useless. If the hardware is forced together, the zinc coating is ground off as you assemble your H-Stands, leaving you with exposed plain steel. Stainless steel hardware would be a much simpler choice and it’s better suited for use in corrosive environments.

With framing and hardware available in a variety of finishes, our experienced team of rooftop professionals can design an H-Stand that can support your pipes and duct work in almost any rooftop environment. Designed to meet your specific project needs, our H-Stands will help you take your next project from concept to completion.