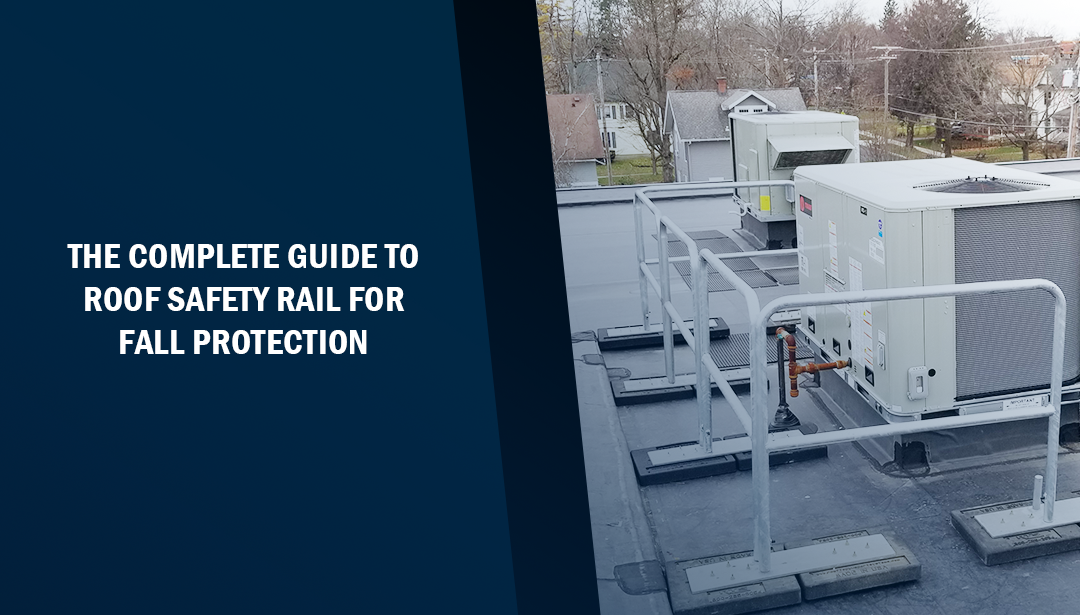

Roof Safety Rail is an an important component of rooftop safety systems specifically designed to prevent falls and ensure compliance with OSHA fall protection regulations. These systems play an essential role in protecting workers during routine maintenance, inspections, and construction activities on rooftops, where fall hazards are among the most common and severe workplace risks.

By providing a physical barrier at roof edges and elevated surfaces, safety rails reduce the likelihood of accidents and create a secure working environment. roof safety guard rails are most effective when integrated with other safety measures, such as designated rooftop walkways, access platforms, and personal fall arrest systems, forming a comprehensive approach to rooftop safety.

The presence of roof guard rail not only safeguards personnel but also demonstrates a company’s commitment to adhering to regulatory standards and maintaining a culture of safety. Ultimately, investing in roof safety rails is a proactive step toward minimizing injuries and ensuring uninterrupted productivity on elevated work sites.

What Are the Different Types of Roof Safety Rails?

Roof safety rail comes in a variety of types, each designed to meet specific safety needs and installation requirements.

- Permanent roof safety rails are typically installed directly onto the building structure, offering long-term durability and continuous protection for rooftops with frequent worker access.

- Temporary safety rails provide flexibility for short-term projects or maintenance tasks, allowing crews to set up and remove the system as needed without permanently altering the roof.

- Parapet clamp guardrails attach directly to existing parapet walls, making them ideal for roofs where drilling or penetration is undesirable.

- Non-penetrating guardrails, like the kind we manufacture at Rooftop Support Systems, rely on weighted bases to secure the system, preventing damage to the roof membrane.

Each type has unique advantages, from the cost-effectiveness and mobility of temporary systems to the stability and regulatory compliance of permanent installations. This enables companies to select the most appropriate solution for their specific rooftop safety requirements.

When Are Roof Safety Rails Required for Fall Protection?

OSHA regulations provide clear guidelines regarding the use of roof safety rails, emphasizing their necessity based on roof height, slope, and specific work conditions. Roof safety railing is generally required on roofs where employees are exposed to fall hazards of six feet or more above a lower level, particularly along unprotected edges and around roof openings.

They are also essential during maintenance, construction, or repair tasks where workers may be at risk of slipping or losing balance due to the roof’s slope or surface conditions. Proper implementation of roof safety rails not only ensures compliance with OSHA standards but also significantly reduces the likelihood of accidents, injuries, and fatalities on the job site.

Employers who adhere to these guidelines benefit from enhanced workplace safety, improved employee confidence, and the avoidance of potential fines or legal liabilities associated with non-compliance. By understanding and following OSHA requirements, companies can create a safer, more productive environment for all rooftop operations.

How to Choose the Right Roof Safety Guard Rails

Selecting the most suitable roof safety rail system requires careful consideration of several key factors to ensure optimal safety and compliance. Begin by assessing the roof type and structure, including slope, material, and potential attachment points, as these will influence which system is compatible and effective.

Next, consider the frequency of rooftop access. Permanent systems are ideal for regular use, while temporary or non-penetrating rails may be better suited for occasional maintenance tasks. Environmental conditions such as wind, snow, and UV exposure should also guide your choice, ensuring the system can withstand local weather without compromising safety.

Additionally, evaluate how the safety rails will integrate with existing rooftop safety systems, including walkways, ladders, and fall arrest equipment, to create a comprehensive solution. When reviewing products, focus on durability, OSHA compliance, and ease of installation, as these factors will affect both long-term performance and employee adoption. By following these steps, you can select a roof safety rail system that maximizes protection while remaining practical and cost-effective.

Installing Roof Safety Rails: Best Practices

The installation of roof safety rails begins with careful preparation, including a thorough assessment of the roof structure, identification of potential hazards, and gathering of the appropriate tools and materials. During installation, it is essential to follow manufacturer guidelines and employ proper techniques, ensuring that each rail is securely anchored, evenly spaced, and positioned to provide maximum fall protection.

Safety checks should be performed throughout the process, including verifying the stability of posts, testing connections, and confirming that guardrails meet OSHA height and strength requirements. Professional installation is highly recommended, as it ensures compliance with safety standards and maximizes the effectiveness of the system, reducing the risk of accidents.

Common pitfalls to avoid include failing to secure rails properly, neglecting to account for roof slope or environmental conditions, and spacing guardrails too far apart, all of which can compromise worker safety. By adhering to best practices and professional standards, organizations can confidently provide a safe rooftop environment for their employees.

Maintaining Roof Safety Railing for Long-Term Performance

Regular maintenance is essential to ensure that roof safety rails remain effective and compliant over time. Routine inspections should be conducted to check for loose fasteners, corrosion, cracks, or other signs of wear that could compromise structural integrity. Cleaning the rails periodically helps prevent buildup of debris, dirt, or ice that might affect stability or create slip hazards.

Any damaged components should be repaired or replaced promptly to maintain full protection for workers and compliance with OSHA regulations. Key signs of wear to watch for include bent or warped rails, rust on metal components, and weakened anchor points. By performing consistent maintenance, companies not only extend the longevity of their roof safety systems but also reinforce a culture of safety, ensuring that employees can work on elevated surfaces with confidence and minimizing the risk of accidents.

Enhancing Rooftop Safety with Complementary Systems

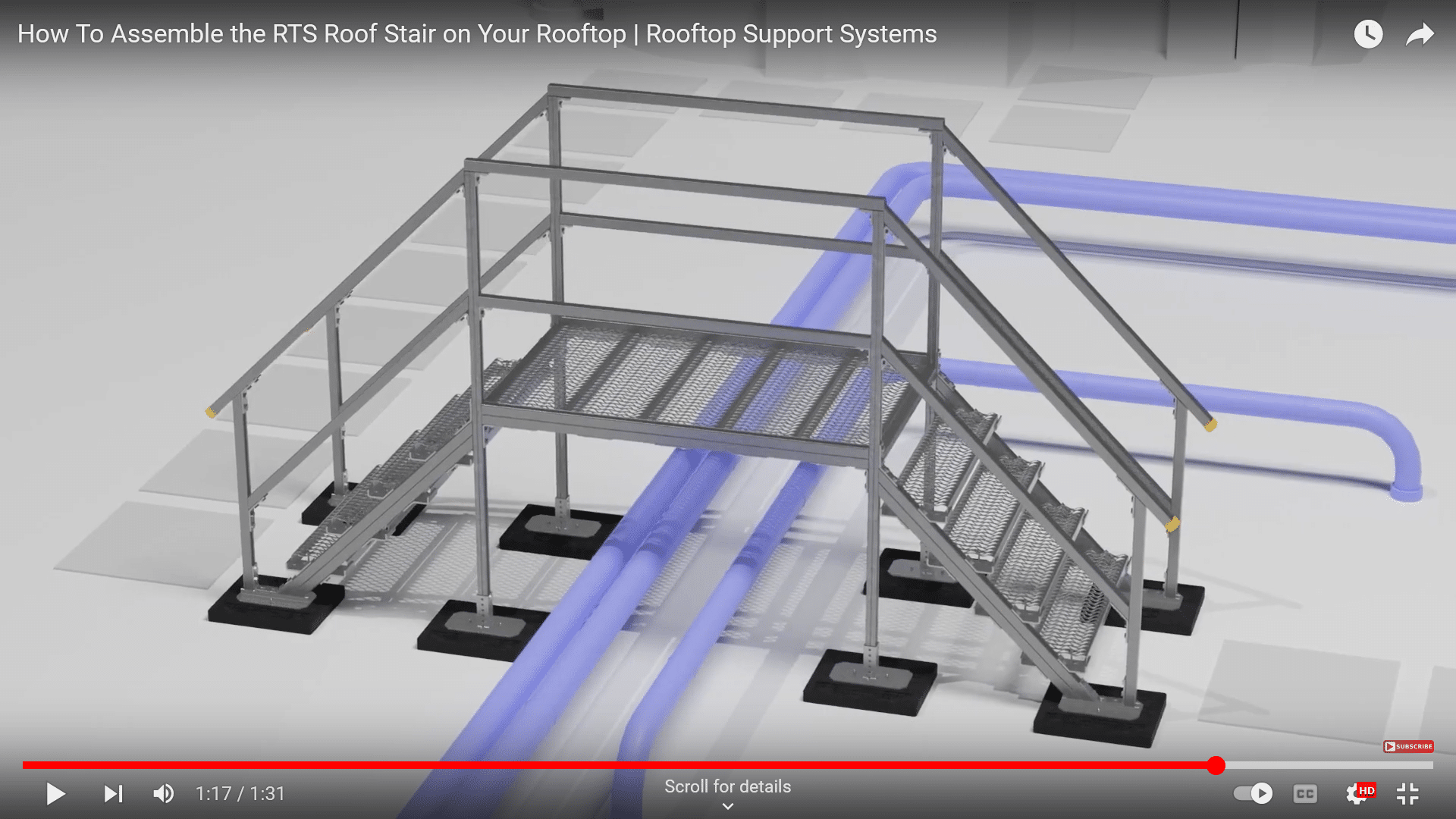

Roof safety rails are most effective when integrated with other rooftop safety products, creating a comprehensive fall protection system. Combining guardrails with walkway systems ensures safe navigation across potentially hazardous roof surfaces, while access platforms provide stable points for entry, exit, and maintenance activities.

In addition, pairing rails with personal fall arrest systems offers an extra layer of protection for workers operating near edges or openings, reducing the risk of serious injury. This holistic approach to fall protection not only addresses multiple types of hazards but also reinforces safe work practices and compliance with OSHA standards.

By implementing a coordinated system of safety measures, organizations can create a secure rooftop environment that safeguards employees, minimizes downtime, and fosters a culture of proactive risk management. The synergy of these combined solutions ensures that safety is built into every aspect of rooftop work.

Roof Safety Rail Products by Rooftop Support Systems

When it comes to high‑quality roof safety rail systems, Rooftop Support Systems offers several standout products designed to deliver durability, simplicity of installation, and full compliance with key safety standards. Our Roof Railing for Rooftop Guard Rail Systems is fabricated in‑house from schedule 40 pipe (1¼″) and is available in hot‑dip galvanized or safety‑yellow powder‑coated finishes, giving robust protection and strong visual presence.

These systems are designed to meet the requirements of OSHA standards 29 CFR 1910.29 and 1926.502, as well as the International Building Code (IBC) 2002 edition, giving peace of mind that they support regulatory compliance.

At RTS, we also emphasize strong customer service and fast lead times, which many clients have cited as a defining benefit. In practice, these systems have been successfully implemented on a variety of projects, ranging from large commercial rooftops needing permanent edge protection to more modest installation sites requiring custom lengths and finishes, enhancing safety and elevating compliance across the board.

Ready to Get Started with us on your next Rooftop Project?

1 (888) 243-2669