It should be no surprise that the category of seismic bracing comes with countless requirements and a significant amount of red tape. After all, the components that these seismic bracing systems are composed of are intended to withstand the most catastrophic of events at a moments notice.

Unsure of your projects’ needs in relation to rooftop seismic bracing requirements? Follow this guide for a better understanding of seismic bracing systems, their requirements, and how they function in real-world rooftop applications. Proactively protecting property and lives is best accomplished by closely adhering to seismic bracing requirements.

What Is Seismic Bracing?

By definition, seismic bracing refers to structural support systems designed to stabilize buildings, equipment, or infrastructure against forces of nature such as earthquakes or inclement weather with extremely high winds. These systems are intended to prevent damage by minimizing movement and ensuring that critical elements remain intact.

The three most common types of bracing include: structural bracing for building framework, equipment bracing for generators and other machinery, and non-structural bracing which is used to secure non-structural elements such as mechanical, electrical, and plumbing systems, as well as HVAC units and suspended ceilings.

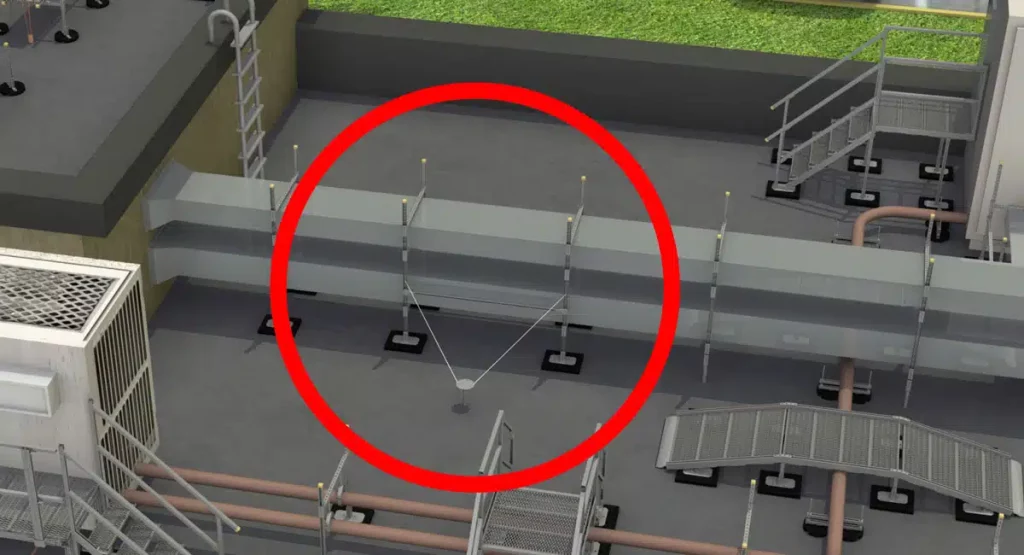

Rooftop Supports Systems specializes in the third aforementioned method, securing non-structural elements, such as roof pipe supports, roof duct supports, roof stairs, rooftop HVAC equipment, and other rooftop structures to your roof. This is accomplished through various means, including the use of direct mount bases that get flashed into your rooftop, and tie-down bases to secure structures with cabling. Non-structural seismic bracing systems are crucial in protecting people, duct work, and other rooftop equipment from lateral movement during seismic activity.

The Importance Of Seismic Bracing Requirements

Seismic bracing requirements are critically important for several reasons. Having such requirements mandatory by law helps to prevent injuries and fatalities of building occupants, as seismic bracing aids in preventing the collapse of structural elements during an earthquake, or the possibility of rooftop equipment becoming unstable during a high wind scenario. Properly braced structures greatly reduce the risk of falling debris that could cause injuries or fatalities. Seismic bracing requirements also protect property through minimizing damage, which in turn reduces repair and replacement costs after major catastrophic events.

Having seismic bracing in place on the rooftops of schools, hospitals, and other essential infrastructure ensures that these facilities will remain operational after an earthquake.

Without proper seismic bracing on rooftops, electrical, air, heating/cooling, and plumbing could become completely compromised, leaving individuals without essential needs in the wake of a disaster. Without properly secured rooftop units, the lives of workers and pedestrians below are at risk. Rooftop seismic bracing is essential for public safety and the community’s ability to respond to and recover from disaster. As mentioned previously, seismic bracing is mandated by law and required for compliance with building codes in geographic areas where seismic activity is pronounced.

Designing Effective Bracing Systems

Designing effective bracing systems for rooftops that are compliant with seismic bracing requirements involves careful review of several aspects including structural analysis, material selection, and code compliance to name a few.

- Structural Analysis – This step consists of gathering both seismic load calculations and dynamic analysis information. Seismic load calculations measure factors such as location, soil type, building height, and mass distribution. Dynamic analysis determines how the structure will respond dynamically to seismic forces or extreme stress from inclement weather and high winds. The information provided by these two methods helps guide the design of the bracing system.

- Material Selection – When deciding upon material selection, it is important to acknowledge seismic bracing should have high ductility, allowing parts to absorb and dissipate energy without fracturing. Another essential aspect to consider is strength of material. Materials must be strong enough to resist seismic forces or high winds without yielding or breaking. The choice of materials should also consider the building’s overall weight and the impact on its seismic performance. Steel is an example of a popular choice due to its excellent ductility and strength ratings. Our direct mount bases are made entirely from steel, ensuring maximum performance.

- Redundancy and Resilience – Incorporating redundancy into your seismic bracing system ensures that if one part of the bracing system fails, other parts can still carry the load. This increases the overall resilience of the structure. The bracing system should also be designed to prevent progressive collapse, where the failure of one element leads to the failure of others, causing a chain reaction.

- Code Compliance & Testing – The seismic brace system’s design must comply with local and international building codes and standards, such as the International Building Code (IBC) or the American Society of Civil Engineers (ASCE) standards, which provide guidelines for seismic design. Before implementation, the design should be validated using computer simulations and modeling to predict its performance during an earthquake. Where feasible, physical testing of components or scale models may be conducted to verify the effectiveness of the bracing system under simulated seismic conditions.

- Site-Specific Considerations – When examining location, rooftop surface material and seismic hazard probability must be considered. Common rooftop surface materials include rubber membrane, steel, and concrete, each requiring a different method for affixing seismic bracing. When determining the seismic hazard assessment, the design must account for the specific seismic risks of the location, including the likelihood and potential magnitude of earthquakes.

By carefully considering these key elements, engineers can design seismic bracing systems that effectively protect buildings and their occupants during extreme weather conditions or earthquakes.

Common Challenges In Seismic Bracing

When implementing seismic bracing systems onto rooftops, there are several common obstacles that projects run into. However, with careful planning and strategy, these challenges can be effectively managed. Some of the most common obstacles include cost constraints, code compliance, and material consideration.

Cost constraint obstacles are common as seismic bracing can be expensive, especially for existing buildings or when high-performance systems are required. The best solution is focusing on prioritization and phased implementation. Focusing on bracing critical areas or components first, such as emergency exits, essential equipment, and structural elements is key as they are most vulnerable. By spreading out the cost through implementing the bracing system in phases, budget allocation can be spread over several years.

Navigating complex building codes and regulations related to seismic bracing can be difficult, especially in regions with evolving seismic standards. We suggest working with structural engineers and code experts who are familiar with local regulations. Their expertise can help ensure compliance and avoid costly redesigns. Also, by engaging with local building authorities early in the design process, you can clarify requirements and obtain necessary approvals without worry of missing any key aspects.

When designing a seismic bracing system for rooftops, one must consider the material of the rooftop and how to best pair that with seismic bracing options. Different materials require different solutions. For rooftops with rubber membranes, direct mount bases can be flashed into the roof. Other common materials such as concrete and steel will require drilling to ensure the direct mount bases are properly secured to the roof.

Real-World Applications And Case Studies

The following two examples of real-world application of seismic bracing systems both involve hospitals, which are considered Risk Category 4 Structures. It is vital that they remain open during times of disaster.

Our first example is an essential hospital in the city of Los Angeles. The LA County+USC Medical Center underwent a seismic retrofit to comply with California’s stringent hospital seismic safety standards. The retrofit included base isolators and shear walls to enhance the hospital’s ability to remain operational during and after an earthquake. The retrofit focused on ensuring that the hospital could continue functioning in the aftermath of an earthquake, which is vital for public health and emergency response. Adherence to California’s seismic regulations for hospitals drove the design and implementation, highlighting the importance of regulatory frameworks in guiding seismic retrofits. The key takeaways from this example were the attention to operational continuity and the close collaboration with the government to ensure the project met safety standards and public needs. For critical facilities like hospitals, however, seismic bracing must go beyond protecting the structure; it must ensure that essential services remain operational during emergencies.

Our second example involves a major hospital on the East Coast. The Rooftop Support Systems team was tasked with designing and installing custom roof duct supports for a hospital in Buffalo, NY. Designing a custom seismic bracing system for an existing rooftop requires both careful consideration of client needs, as ell as seismic bracing requirements, balancing those two while staying compliant on requirements.

In order to maintain compliance with this project, roof anchors were used to permanently attach the duct supports to the roof. This ensured rooftop equipment would be able to withstand 120 mph winds while staying operational in extreme weather circumstances.

Seismic bracing for rooftops is a critical component in the design and construction of buildings, infrastructure, and equipment in earthquake-prone areas. Adhering to seismic bracing regulations is not just a legal requirement – it is a moral obligation to protect lives and property.

Building codes and standards are designed based on extensive research and experience to ensure that structures can withstand the forces generated by earthquakes. By following these regulations, you contribute to a safer built environment, reduce the risk of catastrophic damage, and support the resilience of your community. Investing in proper seismic bracing is an investment in safety, stability, and peace of mind. Whether you are building new structures or retrofitting existing ones, prioritize seismic bracing and ensure that your projects meet or exceed regulatory standards. The safety and well-being of individuals and the community depend on it.

Rooftop Support Systems is here to assist with any rooftop seismic bracing project. We provide expert consultation, custom solutions fit to your needs, and comprehensive support at every step of the way. Visit our Wind & Seismic Bracing page for more information.

Have a project and in need of guidance?

Let our experts assist you in making the right decision!